Tested & Proven

Tested & Proven

Tested by scientists.

Proven by builders.

Tested by scientists.

Proven by builders.

For over 20 years, Nu-Rock has worked closely with highly respected academic institutions, industry associations and scientific organisations such as CSIRO, EPA, UNSW, ANSTO, Western Sydney University and Wollongong University to ensure the ongoing refinement and improvement of Nu-Rock’s core technology.

For over 20 years, official testing by independent Engineering Departments and Testing Laboratories have consistently proven that Nu Rock products meet and surpass all standards.

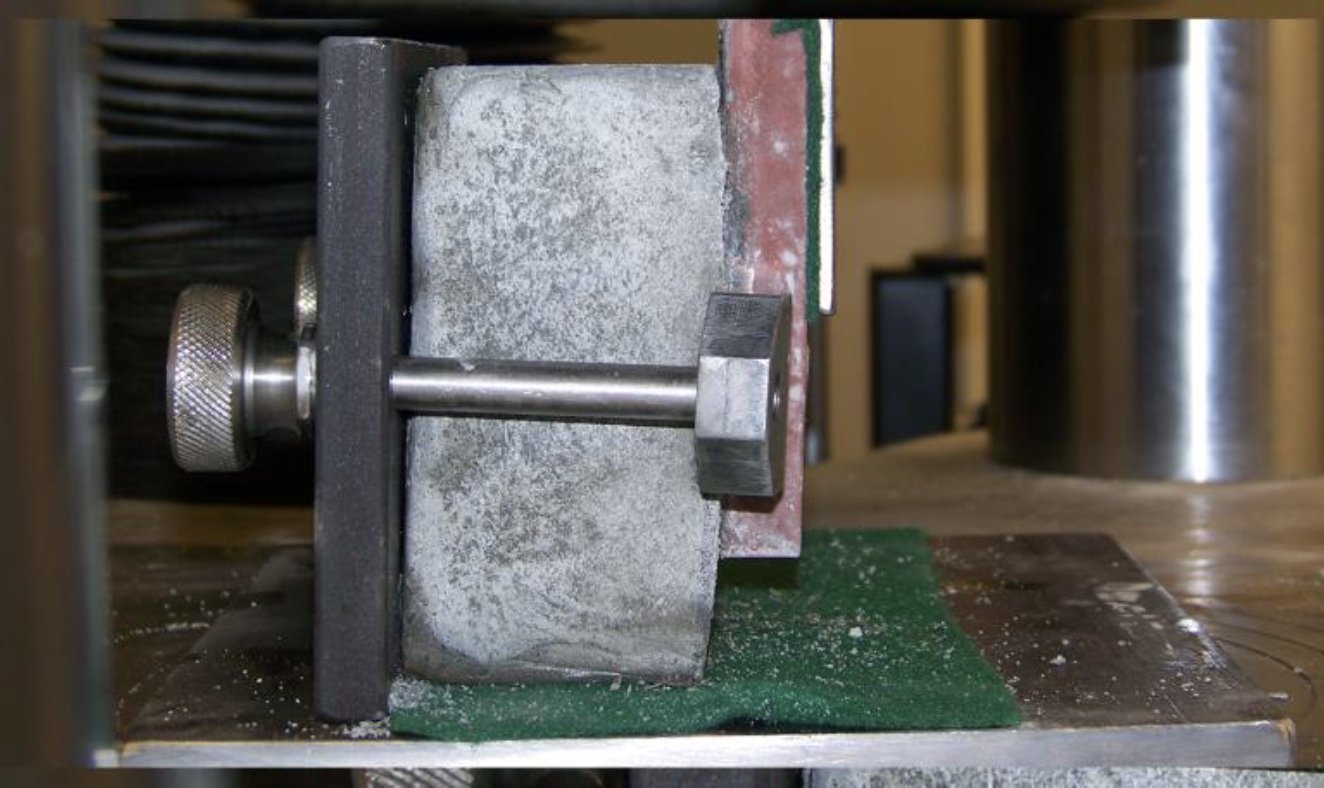

Building Product Tests

Compressive Strength, Lateral Strength, Thermal Rating, Fire Rating, Salt Attack, Water Absorption and Carbon Absorption

Railway Sleeper Tests

Axle load Disbursement and Vibration Absorption

Importantly, Nu-Rock testing projects, conducted at the Nu-Rock Testing Facility at Mt.Piper Power Station have involved the trialing of waste materials such as Coal Ash, Biomass, Steel Slags and Dusts, Non-Ferrous Metal slags and dust from Red Mud, Hard Rock Mine Tailings and Coal Washery Tailings from dozens of Australian and overseas companies.

Recent testing and trialing involving the integration of up to 35% household waste plastics, glass, paper pulp and rubber tyres with other waste streams have achieved ‘ground-breaking’ results.

Nu-Rock Blocks, Bricks and Pavers have been used successfully in a variety of Australian construction projects for the past 20 years. Projects have included luxury homes, commercial buildings and even a large-scale luxury waterfront residential development. Over ten thousand buildings and social housing dwellings in South Africa were built with Nu-Rock blocks made from 95% Steel slag and dusts wastes generated by the Steel Mill participating in the venture. All solid waste streams were used proportionally to their volume of generation.